- Home »

- Our Lumber »

- True QuarterSawn

True QuarterSawn

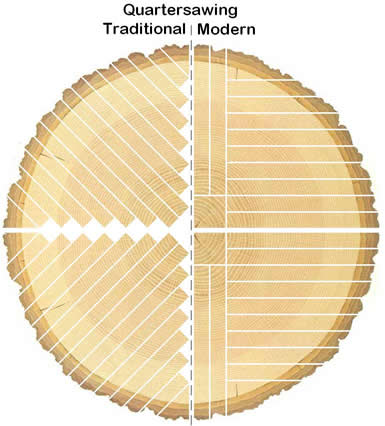

True quartersawn lumber is produced when the growth rings of the log are sawn as close to perpendicular as possible. Each board produced using this method of sawing possesses grain patterns that are both unique and beautiful. In addition to this, quartersawning produces lumber that is inherently more stable than plain sawn lumber. These features make quartersawn lumber an excellent choice for high quality flooring, millwork, or furniture.

At Brownlee Lumber, we use modern sawing equipment and technology to produce some of the finest quartersawn lumber in White Oak, Red Oak, and Black Cherry. Our Rift & Quartered lumber is a True Quartersawn product produced using traditional sawing methods, guaranteeing you the best figure and grain pattern possible.

Prime Rift & Quartered

- Is put up 4” (4.0”) & wider, unselected for color. Lengths are typically sorted as 6'-8', 9'-10', 11'-12', and 13'-16'. Customers can request loads that meet their optimum length requirements.

- BLC Prime Rift & Quartered wane restrictions greatly exceed NHLA rules, providing an exceptional square edge product for increased customer yield. BLC only allows in the aggregate, 1/3 the length (NHLA ½) and ¼ the width (NHLA 1/3).

- BLC Prime Rift & Quartered is a true random width product with no widths pulled, resulting in a better average width and includes all the wide clear boards produced as we do not pull any clear stock from our Prime Rift & Quartered

- BLC Prime Rift & Quartered makes an excellent choice for distribution yard stock.

1Com Rift & Quartered

- Is put up 4” & wider, unselected for color. Lengths are typically sorted as 6'-8', 9'-10', 11'-12', and 13'-16'.

- Inspectors greatly limit wane for increased customer yield.

2a Com Rift & Quartered

- Is put up 4” & wider, unselected for color. Lengths are typically sorted as 6'-8',, 9'-10', 11'-12', and 13'-16'.

- Inspectors greatly limit wane for increased customer yield.

BLC has surfacing facilities available on site and can S2S to your specific requirements. Additional sorting is also available at the customers request after surfacing as this may reveal defects not seen in the rough. These may include color issues, checking, planer splits, pin knots, thin ends or thin boards, etc..